Benefits of our chamfering machines and pipe beveling machines include:

- No more hand-grinding or torching of weld bevels

- Automated pipe beveling machines are many times faster than portable units

- Cycle normally in the 5-20 second range

- Safer than handgrinding

- Accurately machines weld bevel and faces pipe square

- Sturdy construction and quality materials for years of dependable service

- Pipe beveling machines have low operating costs and virtually no maintenance

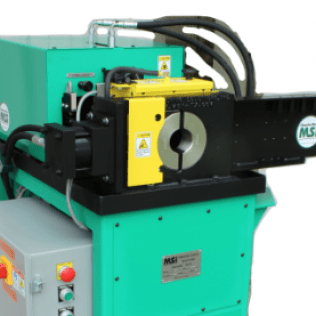

Features of our chamfering machines and pipe beveling machines include:

- Machines available for ½” up to 8″ OD pipe or tubing

- Adjustable cutter head quickly set with gauges

- Uses standard off-the-shelf carbide inserts. Tooling is available for custom angles and J-bevels

- Interchangeable grips for different size pipe or tubing

- Electronic variable-speed drive

- Heavy-duty spindle that rides on machine tool-type linear ball rails

- Totally enclosed cutting area to protect the operator

- Large chip drawer for easy waste removal

Products proudly made in the USA

Products proudly made in the USA