Beveling Pipe Test Coupons for Welding

Manufacturing Solutions Industries has discovered an interesting way to save time and money for organizations training apprentices in the art and science of pipe welding. MSI designs, engineers, and builds the latest technology for automatically beveling a pipe end. This proved to be a very important discovery for many trade schools and union apprentice programs in that it allowed him to automate the production of test pipe coupons for his students to use to practice welding.

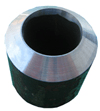

The typical apprentice program lasts a number of years with welders doing a lot of practicing. This extensive training requires the production of a whole lot of test pipe coupons. Most schools bevel the coupons (or prepare the ends of the pipe with the proper angle for welding) by using an oxygen fuel cutter, some type of CNC machine, or even by hand. These process are time consuming and make relatively poor quality edges for his students to bevel, requiring more weld prep time and less weld instruction time for the students.

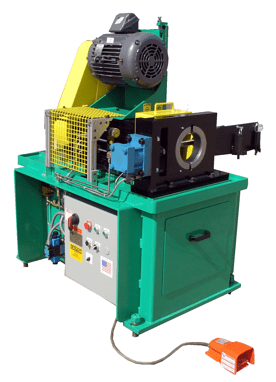

Enter the MSI Chamfermate automated pipe beveling systems. One of the managers of a union apprentice program has this to say about the ChamferMate. “Since purchasing the C8H from MSI we have seen a tremendous increase in test coupon quality with cleaner edges, while producing the pipe bevel samples in far less time for significantly less money. Not only is our quality much improved but the time to make them has decreased. Our students now have much better samples to work from and it helps us educate them on how to properly weld a beveled pipe”.

ChamferMate® high production chamfering machines and pipe beveling machines are designed for easy setup and operation. Heavy duty construction and quality components are utilized to provide our customers with years of dependable service. Models available for a wide range of diameters and applications such as chamfering, beveling, and deburring.

Automated Pipe Beveling Benefits

Automated Pipe Beveling Benefits Products proudly made in the USA

Products proudly made in the USA

Automated Pipe Beveling Benefits

Automated Pipe Beveling Benefits